Cam Houseman

Member

Hi All,

I'm doing some research on the pumping systems of the ship. I read Leading Fireman Frederick Barrett's British Testimony, and he said this:

2024. Then what was the next order?

- He asked me to lift the manhole plate off.

2025. Where was the manhole plate?

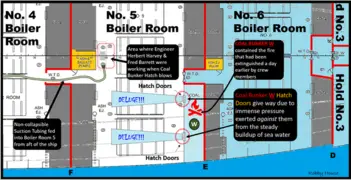

- On the starboard side of No. 5 section.

2026. When the plate was in position what was it - closed?

- It is something you lift up to get at the valves. I do not know what valves it is. It is just like a hole in this table. You lift it off to get to the valves to turn on the pumps or something.

2027. Is it in the floor?

- Yes.

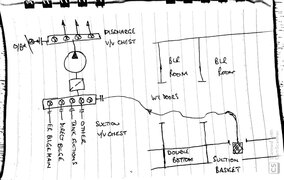

If I recall correctly, someone testified that the Engineers managed to redirect the pumps to pump out the incoming water, probably out the discharge washports in the Turbine Room? (Based on Lifeboat 13's testimony of a large volume of water being pumped out the side) But How did they do this? It looks like something with the Circulating Pumps were involved.

Thanks for any help, I appreciate it.

I'm doing some research on the pumping systems of the ship. I read Leading Fireman Frederick Barrett's British Testimony, and he said this:

2024. Then what was the next order?

- He asked me to lift the manhole plate off.

2025. Where was the manhole plate?

- On the starboard side of No. 5 section.

2026. When the plate was in position what was it - closed?

- It is something you lift up to get at the valves. I do not know what valves it is. It is just like a hole in this table. You lift it off to get to the valves to turn on the pumps or something.

2027. Is it in the floor?

- Yes.

If I recall correctly, someone testified that the Engineers managed to redirect the pumps to pump out the incoming water, probably out the discharge washports in the Turbine Room? (Based on Lifeboat 13's testimony of a large volume of water being pumped out the side) But How did they do this? It looks like something with the Circulating Pumps were involved.

Thanks for any help, I appreciate it.