Cian O'Reilly

Member

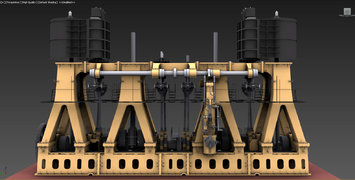

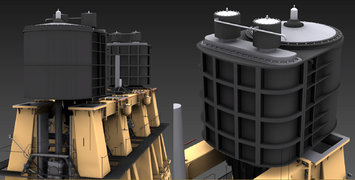

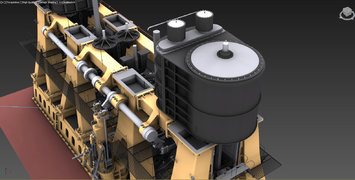

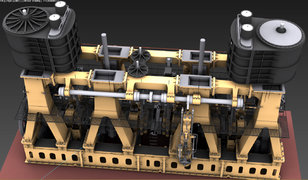

More progress on the Reversing engine...It's tough work, with the available plans being somewhat difficult to interpret for a non-expert like me. Often, photo's of Britannic's engines help to shed light on things like this and while they have been of some help, there are fairly big differences between them and the plans (assuming I'm making a reasonable interpretation of the plans).